molybdenum wire

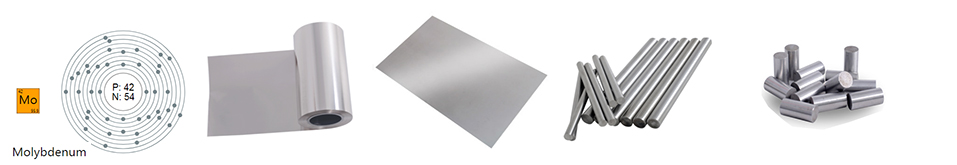

Molybdenum is an exceptional material. It is twice lighter per

tungsten and has a high specific strength. Molybdenum wire is

intensively used in light and heavy industries, as the metal is

characterized by high heat resistance, refractoriness, and excellent

ability to resist corrosion.

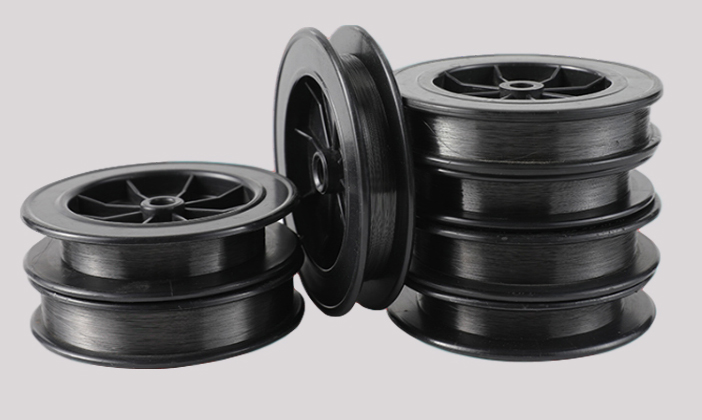

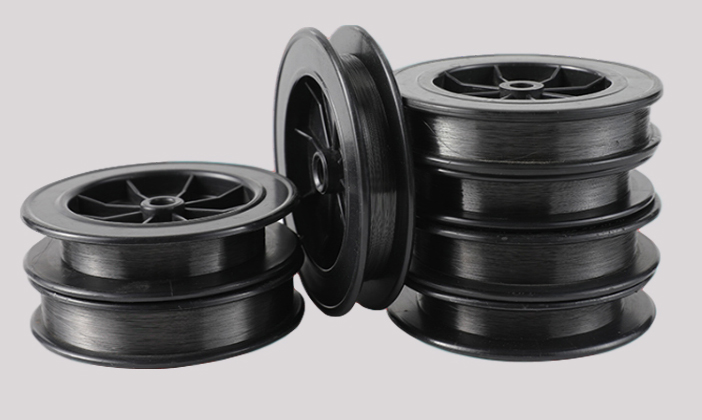

Most often Molybdenum wire has a diameter of 0.01-4 mm, as well as a

smooth and even surface on which all kinds of defects are completely

absent.It can be presented in various shades of gray: from almost black

to silver.It is stored in a dry room, transported with extreme care.

Molybdenum wire is widely used in radio engineering, electrical and a

number of other industries, in particular, in the manufacture of vacuum

devices, mirrors, light sources, heating elements of high-temperature

furnaces, various medical equipment, thermocouples and much more.

According to the requirements for molybdenum wire, on its surface there

should be no traces of oxidation, greases and other types of pollution.

Molybdenum wire with a thickness of up to 0.4 mm is produced in dark

gray or black, thicker sizes have a light gray tint. The surface of the

molybdenum wire should be free of cracks and burrs, but requirements for

thicknesses greater than 0.5 mm are less stringent, burrs that are true

do not go beyond tolerances.

Molybdenum wire is highly resistant to the influence of the highest

temperatures and mechanical damage, it is not prone to rust and can be

located where there is the influence of hostile spheres, such as

alkaline solutions, sulfuric, hydrochloric, hydrofluoric acids. It is

the most reliable when compared with another metal wire. Molybdenum wire

has a low rate of thermal expansion. According to a comparison with

another known alloy - tungsten, molybdenum is the lightest, which

provides enormous specific strength at temperature differences up to

1370 ° C. This alloy does not tend to oxidize under the influence of low

temperatures. Alloys doped with molybdenum, as well as titanium, are

ready to normally perceive heating up to such a temperature as 1500 °

C..

;

.

molybdenum

Cobalt

Iron

Carbon

Sulfur

Copper

Zinc

Lead

Total Impurities

99.99

<0.00002

0.002

<0.01

0.0002

0.00005

0.00005

0.00002

<0.01

Diam

thickness

length

width

purity

Details

Foil

0.03mm -0.8mm

>3000mm

2mm-150mm

99.99%

Details

sheet

0.03mm-50mm

100mm

100mm

99.99%

Details

wire

0.025mm

-0.05mm

7000-8000m

99.99%

Details

Stab

2.0mm

-150mm

<1000mm

99.99%

Details

powder

50nm- 20μm

99.99%

Details

Pellets

6mm-13mm

99.99%

Details

granules

6mm-13mm

99.99%

Details

Sputter

target

3mm-300mm

O30--2000mm

99.99%

Details

crucible

30ml-50ml

99.9%

Details

mesh

0.05-2mm

hole:0.3X0.6mm, 0.5X1mm

............20X40mm

99.9%

Details

Molybdenum is an exceptional material. It is twice lighter per

tungsten and has a high specific strength. Molybdenum wire is

intensively used in light and heavy industries, as the metal is

characterized by high heat resistance, refractoriness, and excellent

ability to resist corrosion.

Most often Molybdenum wire has a diameter of 0.01-4 mm, as well as a

smooth and even surface on which all kinds of defects are completely

absent.It can be presented in various shades of gray: from almost black

to silver.It is stored in a dry room, transported with extreme care.

Molybdenum wire is widely used in radio engineering, electrical and a

number of other industries, in particular, in the manufacture of vacuum

devices, mirrors, light sources, heating elements of high-temperature

furnaces, various medical equipment, thermocouples and much more.

According to the requirements for molybdenum wire, on its surface there

should be no traces of oxidation, greases and other types of pollution.

Molybdenum wire with a thickness of up to 0.4 mm is produced in dark

gray or black, thicker sizes have a light gray tint. The surface of the

molybdenum wire should be free of cracks and burrs, but requirements for

thicknesses greater than 0.5 mm are less stringent, burrs that are true

do not go beyond tolerances.

Molybdenum wire is highly resistant to the influence of the highest

temperatures and mechanical damage, it is not prone to rust and can be

located where there is the influence of hostile spheres, such as

alkaline solutions, sulfuric, hydrochloric, hydrofluoric acids. It is

the most reliable when compared with another metal wire. Molybdenum wire

has a low rate of thermal expansion. According to a comparison with

another known alloy - tungsten, molybdenum is the lightest, which

provides enormous specific strength at temperature differences up to

1370 ° C. This alloy does not tend to oxidize under the influence of low

temperatures. Alloys doped with molybdenum, as well as titanium, are

ready to normally perceive heating up to such a temperature as 1500 °

C..

;

.

| molybdenum | Cobalt | Iron | Carbon | Sulfur | Copper | Zinc | Lead | Total Impurities | ||

|---|---|---|---|---|---|---|---|---|---|---|

| 99.99 | <0.00002 | 0.002 | <0.01 | 0.0002 | 0.00005 | 0.00005 | 0.00002 | <0.01 |

| Diam | thickness | length | width | purity | Details | ||

|---|---|---|---|---|---|---|---|

|

Foil | 0.03mm -0.8mm | >3000mm | 2mm-150mm | 99.99% | Details | |

|

sheet | 0.03mm-50mm | 100mm | 100mm | 99.99% | Details | |

|

wire | 0.025mm -0.05mm |

7000-8000m | 99.99% | Details | ||

|

Stab | 2.0mm -150mm |

<1000mm | 99.99% | Details | ||

|

powder | 50nm- 20μm | 99.99% | Details | |||

|

Pellets | 6mm-13mm | 99.99% | Details | |||

|

granules | 6mm-13mm | 99.99% | Details | |||

|

Sputter target |

3mm-300mm | O30--2000mm | 99.99% | Details | ||

|

crucible | 30ml-50ml | 99.9% | Details | |||

|

mesh | 0.05-2mm | hole:0.3X0.6mm, 0.5X1mm ............20X40mm |

99.9% | Details | ||