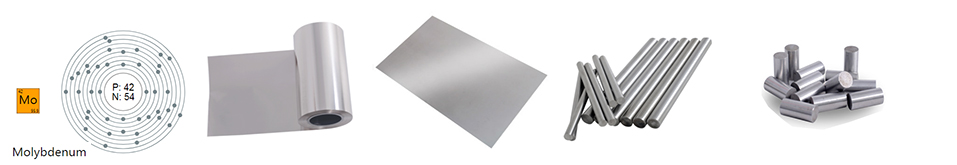

molybdenum Stab

With a melting point of around 2600 ° C, molybdenum is a

slightly lower melting metal than tungsten. However, its properties are

very similar. The sintered material is practically not cold-formable and

brittle at normal temperature.

At temperatures between 1000 and 1600 ° C, the semi-finished products

are given their basic shape by forging, round hammers, rollers or

extrusion. Subsequent grinding of the surface enables workpieces with

very tight tolerances to be produced.

Molybdenum is resistant to most acids, alkalis and non-metals.

(Prerequisite: air humidity <60%; the respective application must be

considered separately). Molybdenum is not stable in oxygen-releasing and

in alkaline liquids at temperatures above 100 ° C. Molybdenum is very

resistant to hydrogen, nitrogen, noble gases, glass and molten metals -

even at very high temperatures. Alloying with other high-melting metals

can further improve the corrosion behavior towards certain media.

Compared to tungsten, molybdenum is easily deformable and easier to

process even at low temperatures. The brittle-ductile temperature during

forming must be taken into account - the thicker the material, the

higher the heating temperature. Above the brittle-ductile temperature,

molybdenum loses its brittleness - it can be reliably deformed without

cracks. Cutting, punching and machining are also possible with the

correct heating temperature.

The main properties of molybdenum

high melting point of 2620 ° C (2893K)

low vapor pressure

high modulus of elasticity

extremely high heat resistance and creep resistance

high thermal conductivity

low coefficient of expansion

excellent corrosion resistance

good workability

Areas of application

Stirrers in glass and metal melts

Carrier for power electronics in semiconductor technology

Components, heating inserts in annealing furnaces, sintering plants

Evaporator crucible

Thermal protection tubes

Sliding coatings

Power supplies in incandescent lamps

Wire mesh

Anti-dazzle caps in automotive lights

Components in chem. Industry

Catalyst components

Heat sinks.

;

.

molybdenum

Cobalt

Iron

Carbon

Sulfur

Copper

Zinc

Lead

Total Impurities

99.99

<0.00002

0.002

<0.01

0.0002

0.00005

0.00005

0.00002

<0.01

Diam

thickness

length

width

purity

Details

Foil

0.03mm -0.8mm

>3000mm

2mm-150mm

99.99%

Details

sheet

0.03mm-50mm

100mm

100mm

99.99%

Details

wire

0.025mm

-0.05mm

7000-8000m

99.99%

Details

Stab

2.0mm

-150mm

<1000mm

99.99%

Details

powder

50nm- 20μm

99.99%

Details

Pellets

6mm-13mm

99.99%

Details

granules

6mm-13mm

99.99%

Details

Sputter

target

3mm-300mm

O30--2000mm

99.99%

Details

crucible

30ml-50ml

99.9%

Details

mesh

0.05-2mm

hole:0.3X0.6mm, 0.5X1mm

............20X40mm

99.9%

Details

With a melting point of around 2600 ° C, molybdenum is a

slightly lower melting metal than tungsten. However, its properties are

very similar. The sintered material is practically not cold-formable and

brittle at normal temperature.

At temperatures between 1000 and 1600 ° C, the semi-finished products

are given their basic shape by forging, round hammers, rollers or

extrusion. Subsequent grinding of the surface enables workpieces with

very tight tolerances to be produced.

Molybdenum is resistant to most acids, alkalis and non-metals.

(Prerequisite: air humidity <60%; the respective application must be

considered separately). Molybdenum is not stable in oxygen-releasing and

in alkaline liquids at temperatures above 100 ° C. Molybdenum is very

resistant to hydrogen, nitrogen, noble gases, glass and molten metals -

even at very high temperatures. Alloying with other high-melting metals

can further improve the corrosion behavior towards certain media.

Compared to tungsten, molybdenum is easily deformable and easier to

process even at low temperatures. The brittle-ductile temperature during

forming must be taken into account - the thicker the material, the

higher the heating temperature. Above the brittle-ductile temperature,

molybdenum loses its brittleness - it can be reliably deformed without

cracks. Cutting, punching and machining are also possible with the

correct heating temperature.

The main properties of molybdenum

high melting point of 2620 ° C (2893K)

low vapor pressure

high modulus of elasticity

extremely high heat resistance and creep resistance

high thermal conductivity

low coefficient of expansion

excellent corrosion resistance

good workability

Areas of application

Stirrers in glass and metal melts

Carrier for power electronics in semiconductor technology

Components, heating inserts in annealing furnaces, sintering plants

Evaporator crucible

Thermal protection tubes

Sliding coatings

Power supplies in incandescent lamps

Wire mesh

Anti-dazzle caps in automotive lights

Components in chem. Industry

Catalyst components

Heat sinks.

;

.

| molybdenum | Cobalt | Iron | Carbon | Sulfur | Copper | Zinc | Lead | Total Impurities | ||

|---|---|---|---|---|---|---|---|---|---|---|

| 99.99 | <0.00002 | 0.002 | <0.01 | 0.0002 | 0.00005 | 0.00005 | 0.00002 | <0.01 |

| Diam | thickness | length | width | purity | Details | ||

|---|---|---|---|---|---|---|---|

|

Foil | 0.03mm -0.8mm | >3000mm | 2mm-150mm | 99.99% | Details | |

|

sheet | 0.03mm-50mm | 100mm | 100mm | 99.99% | Details | |

|

wire | 0.025mm -0.05mm |

7000-8000m | 99.99% | Details | ||

|

Stab | 2.0mm -150mm |

<1000mm | 99.99% | Details | ||

|

powder | 50nm- 20μm | 99.99% | Details | |||

|

Pellets | 6mm-13mm | 99.99% | Details | |||

|

granules | 6mm-13mm | 99.99% | Details | |||

|

Sputter target |

3mm-300mm | O30--2000mm | 99.99% | Details | ||

|

crucible | 30ml-50ml | 99.9% | Details | |||

|

mesh | 0.05-2mm | hole:0.3X0.6mm, 0.5X1mm ............20X40mm |

99.9% | Details | ||