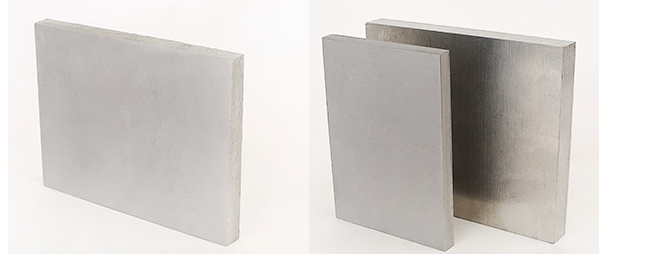

Titanium sheet

Titanium is resistant to chemical influences, titanium sheets are in

demand in the chemical industries, as well as in the food industry.

Titanium is used in the construction industry, pipe production, the

construction of particularly durable load-bearing and support systems.

Easy to weld, amenable to various types of machining, plastic. Titanium

sheet is resistant to vibration, characterized by high resistance to

fatigue loads.

A sheet of titanium is a type of flat-rolled metal.

Specifications

Titanium has a low specific gravity, conducts heat well and forms alloys

with other metals well. Titanium sheets are environmentally friendly, do

not interact with harmful chemicals, light and durable.

Sheets are made by cold or hot rolling. At the same time, cold-rolled

sheets are of higher quality in comparison with hot-rolled sheets. The

technological process begins with forging or stamping from round ingots

of titanium slabs - thick blanks in the form of plates. Then, strips are

formed from the slabs by hot rolling. The surface layer of the

semi-finished product has a brittle structure, saturated with nitrogen,

oxygen, hydrogen, because actively interacts with surrounding gases.

This layer is removed mechanically (stripping, abrasives) and chemically

(etching with molten alkalis or acids). Hot (warm - 650 - 750 oС)

rolling is carried out on semi-continuous and reversible tape mills. The

technological process of cold rolling of titanium sheets involves

intermediate annealing at temperatures from 500 to 900 oС in electric

furnaces or vacuum (to prevent saturation of the surface layer of the

titanium sheet with hydrogen). After the final etching, the protective

properties of the metal are updated.

Sheet titanium is widely used in shipbuilding, space, rocket, and

aviation technology for the manufacture of aircraft and aircraft. The

sheets serve as the casing of the housings, from which they make shafts,

propellers, drives and wings.

Titanium sheet is the raw material for the production of heat

exchangers. In the food, pharmaceutical and chemical industries, cases

of devices and equipment are produced from it. Thanks to the use of this

metal, an effective, mass production of urea, potassium, soda, chlorine,

and various household cleaning products has been established. Cases of

high-quality household appliances are often made of titanium.

.

.

;

.

Titanium

Cobalt

Iron

Carbon

Sulfur

Copper

Zinc

Lead

Total Impurities

99.99

<0.00002

0.002

<0.01

0.0002

0.00005

0.00005

0.00002

<0.01

Diam

thickness

length

width

purity

Details

raw

material

99.5%

details

Foil

0.03mm -0.8mm

>3000mm

2mm-150mm

99.99%

Details

sheet

0.03mm-50mm

100mm

100mm

99.99%

Details

wire

0.025mm

-0.05mm

7000-8000m

99.99%

Details

Stab

2.0mm

-150mm

<1000mm

99.99%

Details

powder

50nm- 20μm

99.99%

Details

Pellets

6mm-13mm

99.99%

Details

granules

6mm-13mm

99.99%

Details

Sputter

target

3mm-300mm

O30--2000mm

99.99%

Details

crucible

30ml-50ml

99.9%

Details

mesh

0.05-2mm

hole:0.3X0.6mm, 0.5X1mm

............20X40mm

99.9%

Details

foam

0.3-10mm

100mm

100mm

Details

Titanium is resistant to chemical influences, titanium sheets are in

demand in the chemical industries, as well as in the food industry.

Titanium is used in the construction industry, pipe production, the

construction of particularly durable load-bearing and support systems.

Easy to weld, amenable to various types of machining, plastic. Titanium

sheet is resistant to vibration, characterized by high resistance to

fatigue loads.

A sheet of titanium is a type of flat-rolled metal.

Specifications

Titanium has a low specific gravity, conducts heat well and forms alloys

with other metals well. Titanium sheets are environmentally friendly, do

not interact with harmful chemicals, light and durable.

Sheets are made by cold or hot rolling. At the same time, cold-rolled

sheets are of higher quality in comparison with hot-rolled sheets. The

technological process begins with forging or stamping from round ingots

of titanium slabs - thick blanks in the form of plates. Then, strips are

formed from the slabs by hot rolling. The surface layer of the

semi-finished product has a brittle structure, saturated with nitrogen,

oxygen, hydrogen, because actively interacts with surrounding gases.

This layer is removed mechanically (stripping, abrasives) and chemically

(etching with molten alkalis or acids). Hot (warm - 650 - 750 oС)

rolling is carried out on semi-continuous and reversible tape mills. The

technological process of cold rolling of titanium sheets involves

intermediate annealing at temperatures from 500 to 900 oС in electric

furnaces or vacuum (to prevent saturation of the surface layer of the

titanium sheet with hydrogen). After the final etching, the protective

properties of the metal are updated.

Sheet titanium is widely used in shipbuilding, space, rocket, and

aviation technology for the manufacture of aircraft and aircraft. The

sheets serve as the casing of the housings, from which they make shafts,

propellers, drives and wings.

Titanium sheet is the raw material for the production of heat

exchangers. In the food, pharmaceutical and chemical industries, cases

of devices and equipment are produced from it. Thanks to the use of this

metal, an effective, mass production of urea, potassium, soda, chlorine,

and various household cleaning products has been established. Cases of

high-quality household appliances are often made of titanium.

.

.

;

.

| Titanium | Cobalt | Iron | Carbon | Sulfur | Copper | Zinc | Lead | Total Impurities | ||

|---|---|---|---|---|---|---|---|---|---|---|

| 99.99 | <0.00002 | 0.002 | <0.01 | 0.0002 | 0.00005 | 0.00005 | 0.00002 | <0.01 |

| Diam | thickness | length | width | purity | Details | ||

|---|---|---|---|---|---|---|---|

|

raw material |

99.5% | details | ||||

|

Foil | 0.03mm -0.8mm | >3000mm | 2mm-150mm | 99.99% | Details | |

|

sheet | 0.03mm-50mm | 100mm | 100mm | 99.99% | Details | |

|

wire | 0.025mm -0.05mm |

7000-8000m | 99.99% | Details | ||

|

Stab | 2.0mm -150mm |

<1000mm | 99.99% | Details | ||

|

powder | 50nm- 20μm | 99.99% | Details | |||

|

Pellets | 6mm-13mm | 99.99% | Details | |||

|

granules | 6mm-13mm | 99.99% | Details | |||

|

Sputter target |

3mm-300mm | O30--2000mm | 99.99% | Details | ||

|

crucible | 30ml-50ml | 99.9% | Details | |||

|

mesh | 0.05-2mm | hole:0.3X0.6mm, 0.5X1mm ............20X40mm |

99.9% | Details | ||

|

foam | 0.3-10mm | 100mm | 100mm | Details | ||