Titanium foam

Titanium Foam is low density permeable material with numerous

applications. The defining characteristic of these foams is a very high

porosity, typically 75-95% of the volume consisting of void spaces.

Ceramic foam is often used for thermal insulation, acoustic insulation,

adsorption of environmental pollutants, filtration of molten metal

alloys, and as substrate for catalysts requiring large internal surface

area. Titanium Foam is generally immediately available in most volumes.

Additional technical, research and safety (MSDS) information is

available

Properties

Titanium foam is made of high-purity titanium powder as raw material,

processed by sieving, cold iso-static pressing, high temperature, high

vacuum sintering.

Uniform structure, narrow pore size distribution and high separation

efficiency.

High porosity, low filtration resistance and high penetration

efficiency.

High temperature resistance, generally can be used below 280 degrees.

Good chemical stability, acid and alkali corrosion resistance, with

antioxidant properties.

No particles fall off, do not make the original liquid secondary

pollution, in line with food hygiene and pharmaceutical GMP

requirements.

Good mechanical properties, can be filtered by suction filtration, easy

to operate.

Low pressure difference, small footprint, large flow.

Strong anti-microbial ability, does not interact with microorganisms.

Under good molding process, and the overall length can be up to 1000 mm.

Can be regenerated, easy to clean, long service life (usually several

times of a ordinary membrane filter)

Applications

With its unique properties, titanium foam can be widely used in the

pharmaceutical industry, water treatment industry, food industry,

bioengineering, chemical industry, petrochemical, metallurgical industry

and gas purification. It is a new material with broad development

prospects.

Typical uses include:

In the infusion of the pharmaceutical industry, small injections, eye

drops, decarbonization filtration in the concentration of oral liquids,

and security filtration before terminal filtration in the lean

distribution.

Removal of impurities in the production process of raw materials,

decarbonization filtration and fine filtration of materials.

Security filtration of ultra-filtration, RO, EDI systems in the water

treatment industry, filtration after ozone sterilization and ozone

aeration.

Clarification and filtration of beverages, white sprinkles, beer,

vegetable oil, mineral water, soy sauce and vinegar in food and

beverage.

Decarbonization filtration and precision filtration of liquid products,

liquid raw materials and pharmaceutical intermediates in the chemical

industry, ultra fine bodies, catalyst recovery, precision filtration

after resin adsorption, system heat transfer oil, material removal and

impurity filtration, catalytic gas Purification and so on.

Oilfield back-flow water filtration, security filtration before reverse

osmosis in the desalination field.

High-temperature decarbonization and de-whitening filtration in the dye

industry.

Filtration of steam, compressed air, catalyst, etc. in gas purification.

As an electrolytic electrode, it can maximize the electrolysis area and

increase the gas evolution rate.

Fun Facts about Titanium

Titanium is a chemical element with the symbol Ti and atomic number 22.

Chinese name 钛. It is a lustrous transition metal with a silver color,

low density, and high strength. Titanium is resistant to corrosion in

sea water, aqua regia, and chlorine

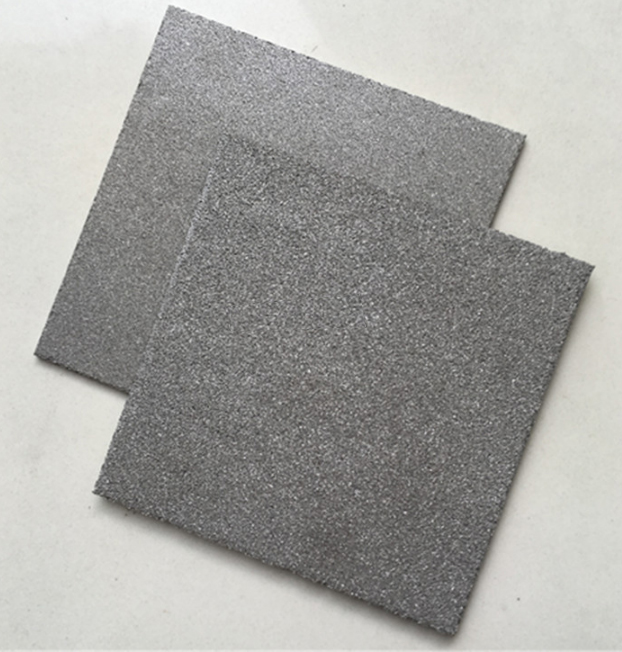

Titanium foam with high purity titanium powder as raw material, after

screen, cold isostatic pressing molding, high temperature, high vacuum

sintering.Thus titanium filter with its high-tech materials and special

molding process, has the unique excellent properties

Color : Light grey

Dimension : 220mm*300mm or customized as request

Thickness : 0.5-2.0mm

Excessive precision (The aperture) : 20-100um

Temperature resistance : 800℃

Application field

Titanium filter with its unique performance, can be widely used in

pharmaceutical industry, water treatment industry, food industry,

biological engineering, chemical industry, petrochemical industry,

metallurgical industry and gas purification field.Is one kind has broad

prospects for development of new materials

.

.

;

.

Other metal foam

nickel foam

titanium foam

iron foam

aluminum foam

copper foam

cobalt foam

silver foam

Zinc foam

carbon foam

Nickel

Molybdenum

Iron Nickel

Cobalt

Nickel

Stainless

steel

Diam

thickness

length

width

purity

Details

raw

material

99.5%

details

Foil

0.03mm -0.8mm

>3000mm

2mm-150mm

99.99%

Details

sheet

0.03mm-50mm

100mm

100mm

99.99%

Details

wire

0.025mm

-0.05mm

7000-8000m

99.99%

Details

Stab

2.0mm

-150mm

<1000mm

99.99%

Details

powder

50nm- 20μm

99.99%

Details

Pellets

6mm-13mm

99.99%

Details

granules

6mm-13mm

99.99%

Details

Sputter

target

3mm-300mm

O30--2000mm

99.99%

Details

crucible

30ml-50ml

99.9%

Details

mesh

0.05-2mm

hole:0.3X0.6mm, 0.5X1mm

............20X40mm

99.9%

Details

foam

0.3-10mm

100mm

100mm

Details

Titanium Foam is low density permeable material with numerous

applications. The defining characteristic of these foams is a very high

porosity, typically 75-95% of the volume consisting of void spaces.

Ceramic foam is often used for thermal insulation, acoustic insulation,

adsorption of environmental pollutants, filtration of molten metal

alloys, and as substrate for catalysts requiring large internal surface

area. Titanium Foam is generally immediately available in most volumes.

Additional technical, research and safety (MSDS) information is

available

Properties

Titanium foam is made of high-purity titanium powder as raw material,

processed by sieving, cold iso-static pressing, high temperature, high

vacuum sintering.

Uniform structure, narrow pore size distribution and high separation

efficiency.

High porosity, low filtration resistance and high penetration

efficiency.

High temperature resistance, generally can be used below 280 degrees.

Good chemical stability, acid and alkali corrosion resistance, with

antioxidant properties.

No particles fall off, do not make the original liquid secondary

pollution, in line with food hygiene and pharmaceutical GMP

requirements.

Good mechanical properties, can be filtered by suction filtration, easy

to operate.

Low pressure difference, small footprint, large flow.

Strong anti-microbial ability, does not interact with microorganisms.

Under good molding process, and the overall length can be up to 1000 mm.

Can be regenerated, easy to clean, long service life (usually several

times of a ordinary membrane filter)

Applications

With its unique properties, titanium foam can be widely used in the

pharmaceutical industry, water treatment industry, food industry,

bioengineering, chemical industry, petrochemical, metallurgical industry

and gas purification. It is a new material with broad development

prospects.

Typical uses include:

In the infusion of the pharmaceutical industry, small injections, eye

drops, decarbonization filtration in the concentration of oral liquids,

and security filtration before terminal filtration in the lean

distribution.

Removal of impurities in the production process of raw materials,

decarbonization filtration and fine filtration of materials.

Security filtration of ultra-filtration, RO, EDI systems in the water

treatment industry, filtration after ozone sterilization and ozone

aeration.

Clarification and filtration of beverages, white sprinkles, beer,

vegetable oil, mineral water, soy sauce and vinegar in food and

beverage.

Decarbonization filtration and precision filtration of liquid products,

liquid raw materials and pharmaceutical intermediates in the chemical

industry, ultra fine bodies, catalyst recovery, precision filtration

after resin adsorption, system heat transfer oil, material removal and

impurity filtration, catalytic gas Purification and so on.

Oilfield back-flow water filtration, security filtration before reverse

osmosis in the desalination field.

High-temperature decarbonization and de-whitening filtration in the dye

industry.

Filtration of steam, compressed air, catalyst, etc. in gas purification.

As an electrolytic electrode, it can maximize the electrolysis area and

increase the gas evolution rate.

Fun Facts about Titanium

Titanium is a chemical element with the symbol Ti and atomic number 22.

Chinese name 钛. It is a lustrous transition metal with a silver color,

low density, and high strength. Titanium is resistant to corrosion in

sea water, aqua regia, and chlorine

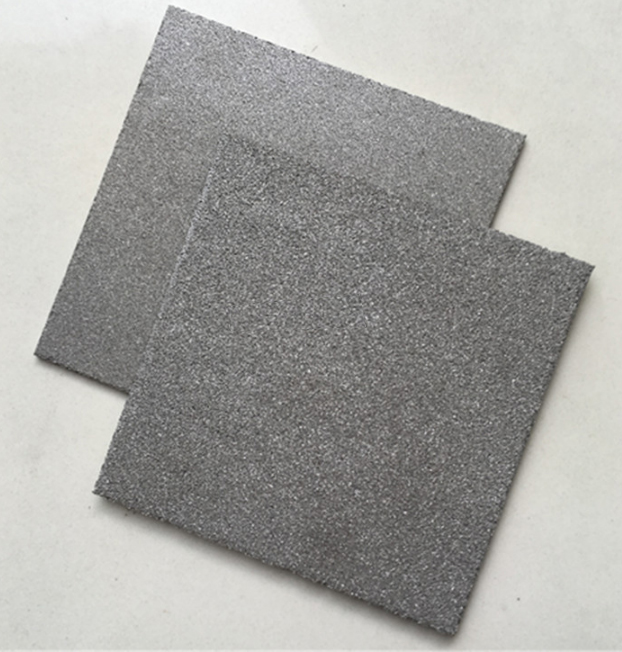

Titanium foam with high purity titanium powder as raw material, after

screen, cold isostatic pressing molding, high temperature, high vacuum

sintering.Thus titanium filter with its high-tech materials and special

molding process, has the unique excellent properties

Color : Light grey

Dimension : 220mm*300mm or customized as request

Thickness : 0.5-2.0mm

Excessive precision (The aperture) : 20-100um

Temperature resistance : 800℃

Application field

Titanium filter with its unique performance, can be widely used in

pharmaceutical industry, water treatment industry, food industry,

biological engineering, chemical industry, petrochemical industry,

metallurgical industry and gas purification field.Is one kind has broad

prospects for development of new materials

.

.

;

.

Other metal foam

| nickel foam | titanium foam | iron foam | aluminum foam | copper foam |

| cobalt foam | silver foam | Zinc foam | carbon foam | Nickel Molybdenum |

| Iron Nickel | Cobalt Nickel | Stainless steel |

| Diam | thickness | length | width | purity | Details | ||

|---|---|---|---|---|---|---|---|

|

raw material |

99.5% | details | ||||

|

Foil | 0.03mm -0.8mm | >3000mm | 2mm-150mm | 99.99% | Details | |

|

sheet | 0.03mm-50mm | 100mm | 100mm | 99.99% | Details | |

|

wire | 0.025mm -0.05mm |

7000-8000m | 99.99% | Details | ||

|

Stab | 2.0mm -150mm |

<1000mm | 99.99% | Details | ||

|

powder | 50nm- 20μm | 99.99% | Details | |||

|

Pellets | 6mm-13mm | 99.99% | Details | |||

|

granules | 6mm-13mm | 99.99% | Details | |||

|

Sputter target |

3mm-300mm | O30--2000mm | 99.99% | Details | ||

|

crucible | 30ml-50ml | 99.9% | Details | |||

|

mesh | 0.05-2mm | hole:0.3X0.6mm, 0.5X1mm ............20X40mm |

99.9% | Details | ||

|

foam | 0.3-10mm | 100mm | 100mm | Details | ||