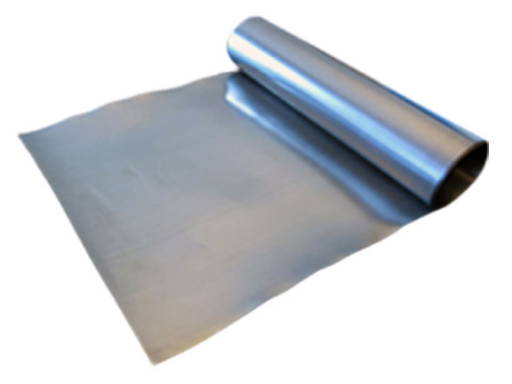

Pure niobium Foil

Not all elements of the periodic table received their own cells

immediately after opening. For example, niobium. Discovered it in 1800,

but recognized after 150 years. In industry, niobium foil has occupied a

certain niche and has strengthened in it, since it has useful

characteristics. Its potential is revealed when used as a raw material

for the creation of alloys, solutions and chemical mixtures.

Niobium foil is in great demand. The production of the main element is

divided into 3 stages:

detection of ore with a high percentage of niobium and its components;

separation of the desired element and tantalum, with which they have

similar properties;

purification of metal and alloys from impurities and their recovery.

The main components of production are:

aluminum;sodium;carbon;heat.Specifications

Many industrial sectors adopt this metal. Rolled products, including

niobium foil, facilitate the process of introducing the main chemical

element into the base compounds. Throughout the process, niobium carbide

is used, which can change the properties of metals and positively affect

their characteristics.

The advantages of this substance are called:

infusibility;

resistance to corrosion;

Improving the heat resistance of substances and their conductive

ability.

Alloying 1 ton of steel requires only 200 g of active ingredient.

Niobium foil during processing improves the characteristics of the

finished product. Such steel is distinguished by:

increased hardness;

plastic;

improved corrosion resistance;

reduced fragility.

Niobium is able to protect non-ferrous metals from the negative effects

of acids and alkalis. When creating various devices and structures, this

metal is used, due to its protective properties.

Use of metal and manufactured products

Niobium foil is usually used in alloying non-ferrous and ferrous metals.

The main industries where the specified chemical element is used:

space technology;

aircraft engineering;

electronics and radio engineering;

chemical engineering.

The uniqueness of the niobium band lies in the absence of interaction of

the substance with uranium at a temperature of less than 1000 ° C.

Positive characteristics allow the use of niobium to protect a nuclear

reactor. The element also lowers the resistance of the conductor to

produce cryotrons.

Therefore, the main "employee" of the nuclear industry is niobium foil.

Its use allows you to create containers for liquid and radioactive

metals..

Niobium

Cobalt

Iron

Carbon

Sulfur

Copper

Zinc

Lead

Total Impurities

99.99

<0.00002

0.002

<0.01

0.0002

0.00005

0.00005

0.00002

<0.01

Diam

thickness

length

width

purity

Details

Foil

0.03mm -0.8mm

>3000mm

2mm-150mm

99.99%

Details

sheet

0.03mm-50mm

100mm

100mm

99.99%

Details

wire

0.025mm

-0.05mm

7000-8000m

99.99%

Details

Stab

2.0mm

-150mm

<1000mm

99.99%

Details

powder

50nm- 20μm

99.99%

Details

Pellets

6mm-13mm

99.99%

Details

granules

6mm-13mm

99.99%

Details

Sputter

target

3mm-300mm

O30--2000mm

99.99%

Details

crucible

30ml-50ml

99.9%

Details

mesh

0.05-2mm

hole:0.3X0.6mm, 0.5X1mm

............20X40mm

99.9%

Details

foam

0.3-10mm

100mm

100mm

Details

Not all elements of the periodic table received their own cells

immediately after opening. For example, niobium. Discovered it in 1800,

but recognized after 150 years. In industry, niobium foil has occupied a

certain niche and has strengthened in it, since it has useful

characteristics. Its potential is revealed when used as a raw material

for the creation of alloys, solutions and chemical mixtures.

Niobium foil is in great demand. The production of the main element is

divided into 3 stages:

detection of ore with a high percentage of niobium and its components;

separation of the desired element and tantalum, with which they have

similar properties;

purification of metal and alloys from impurities and their recovery.

The main components of production are:

aluminum;sodium;carbon;heat.Specifications

Many industrial sectors adopt this metal. Rolled products, including

niobium foil, facilitate the process of introducing the main chemical

element into the base compounds. Throughout the process, niobium carbide

is used, which can change the properties of metals and positively affect

their characteristics.

The advantages of this substance are called:

infusibility;

resistance to corrosion;

Improving the heat resistance of substances and their conductive

ability.

Alloying 1 ton of steel requires only 200 g of active ingredient.

Niobium foil during processing improves the characteristics of the

finished product. Such steel is distinguished by:

increased hardness;

plastic;

improved corrosion resistance;

reduced fragility.

Niobium is able to protect non-ferrous metals from the negative effects

of acids and alkalis. When creating various devices and structures, this

metal is used, due to its protective properties.

Use of metal and manufactured products

Niobium foil is usually used in alloying non-ferrous and ferrous metals.

The main industries where the specified chemical element is used:

space technology;

aircraft engineering;

electronics and radio engineering;

chemical engineering.

The uniqueness of the niobium band lies in the absence of interaction of

the substance with uranium at a temperature of less than 1000 ° C.

Positive characteristics allow the use of niobium to protect a nuclear

reactor. The element also lowers the resistance of the conductor to

produce cryotrons.

Therefore, the main "employee" of the nuclear industry is niobium foil.

Its use allows you to create containers for liquid and radioactive

metals..

| Niobium | Cobalt | Iron | Carbon | Sulfur | Copper | Zinc | Lead | Total Impurities | ||

|---|---|---|---|---|---|---|---|---|---|---|

| 99.99 | <0.00002 | 0.002 | <0.01 | 0.0002 | 0.00005 | 0.00005 | 0.00002 | <0.01 |

| Diam | thickness | length | width | purity | Details | ||

|---|---|---|---|---|---|---|---|

|

Foil | 0.03mm -0.8mm | >3000mm | 2mm-150mm | 99.99% | Details | |

|

sheet | 0.03mm-50mm | 100mm | 100mm | 99.99% | Details | |

|

wire | 0.025mm -0.05mm |

7000-8000m | 99.99% | Details | ||

|

Stab | 2.0mm -150mm |

<1000mm | 99.99% | Details | ||

|

powder | 50nm- 20μm | 99.99% | Details | |||

|

Pellets | 6mm-13mm | 99.99% | Details | |||

|

granules | 6mm-13mm | 99.99% | Details | |||

|

Sputter target |

3mm-300mm | O30--2000mm | 99.99% | Details | ||

|

crucible | 30ml-50ml | 99.9% | Details | |||

|

mesh | 0.05-2mm | hole:0.3X0.6mm, 0.5X1mm ............20X40mm |

99.9% | Details | ||

|

foam | 0.3-10mm | 100mm | 100mm | Details | ||